Electric hovercraft for transporting large loads like a truck | post-ideas.com

Electric hovercraft for transporting large loads like a truck

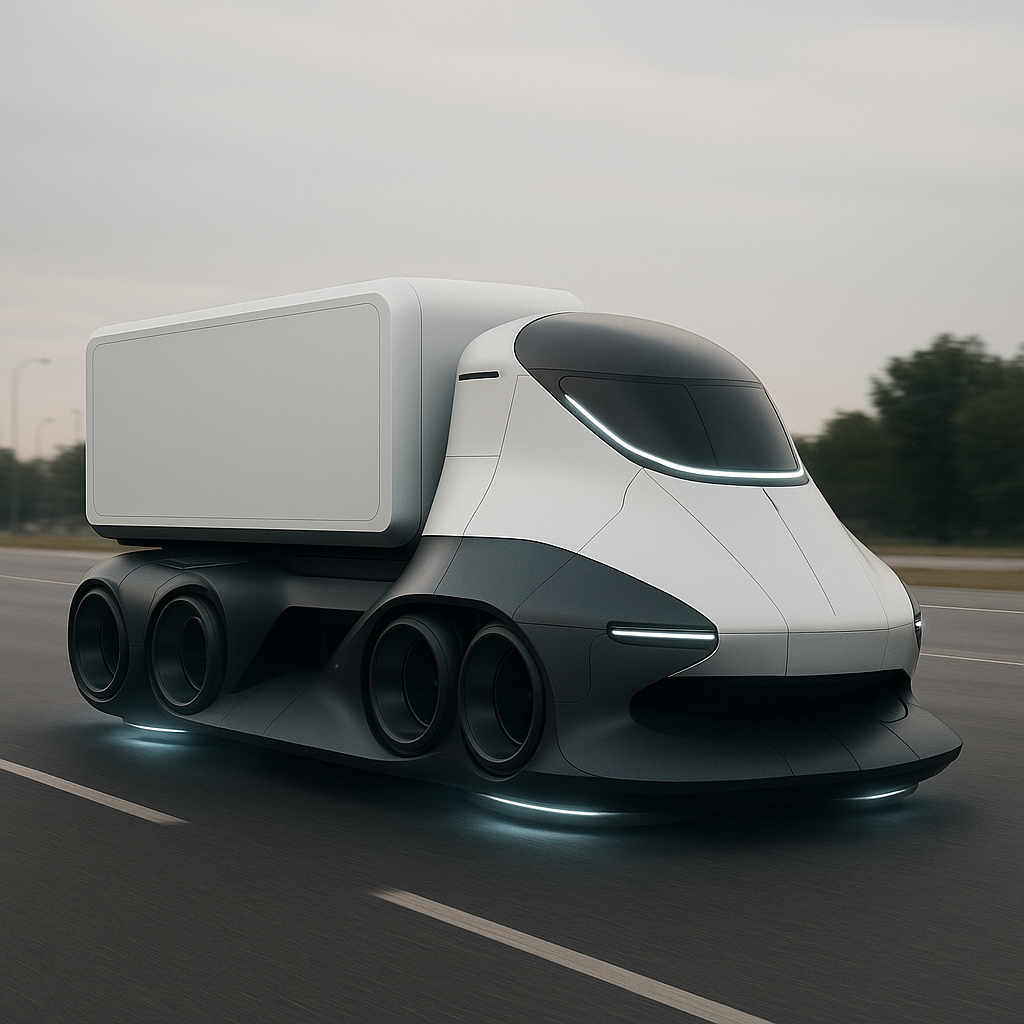

Here’s a design concept for an electric hovercraft cargo hauler — a powerful, futuristic vehicle capable of transporting large loads (equivalent to a truck), operating on roads or open terrain, without resembling a conventional car or truck.

---

Project Name: Aeon Atlas

Core Capabilities

* Electric hovercraft propulsion: Utilizes directed air cushion technology for lift, with vectored thrusters for propulsion and maneuvering.

* On-road + off-road: Optimized for paved surfaces but capable of operating on gravel, sand, or shallow water.

* Cargo capacity: Up to 40 tons, equivalent to a Class 8 truck (semi).

* Modular payload: Flatbed-style cargo platform allows containerized shipping, modular compartments, or open storage.

---

Design Aesthetic: “Alien Utility”

Rather than wheels and chassis, it looks like a fusion of an airship, lunar lander, and monolithic utility craft. Think Star Wars meets Tesla Semi with the elegance of industrial minimalism.

Key Design Features

Hover Base

* Maglev-Assisted Skirt: Low-friction hybrid skirt with segmented directional nozzles. Reinforced side skirts pulse dynamically to maintain cushion shape.

* Shape: Rounded hexagon or teardrop base (30–40 ft long) with a wide rear and tapered front for aerodynamic lift and controlled lateral movement.

* Ground clearance: Adjustable 0.5–3 feet hover height using AI-stabilized lift fans and magnetic assist pads.

Main Body

* Cockpit: Central, elevated command pod with 360° panoramic OLED canopy. The pilot sits like in a drone control station, slightly elevated, not traditional driving.

* Structure: Monocoque carbon-composite shell. Matte or pearlescent finish with embedded LED trim lines for visibility and ambient signaling.

* No windows or grille—all sensors and cameras.

Propulsion and Power

* Lift System: 12 axial lift fans embedded in the base platform powered by dual solid-state battery banks.

* Thrust System: Rear-mounted vectored plasma duct fans for directional speed. Front lateral fans for drift and stability.

* Range: 500–700 miles per charge with regenerative hover braking.

* Solar-Skin Option: Semi-transparent graphene solar layer across flat upper panels.

---

Tech and Autonomy

* Drive-by-wire + AI Co-pilot: Fully autonomous with human override for navigation in mixed traffic.

* Road-ready: Visual light and lidar systems project “virtual wheels” for surrounding vehicle compliance and law enforcement detection.

* No windshield, mirrors, or visible headlights – all visibility via AR and external projection systems.

* Traffic Integration: Holographic license/ID projection, soundless horn pulses, and standard brake/turn lighting translated from AI behavior.

---

Power System

* Battery Packs: Swappable modules integrated into the underbody.

* Cooling System: Liquid-cooled superconducting circuits with radiant cooling fins visible at the rear like a spaceship engine block.

* Charging: Fast-charging via inductive ground stations or tethered plug-ins at hover depots.

---

Cargo Handling

* Automated Docking Bay: Rear or side entry ports that align with logistics centers.

* Magnetic Locking Pallet System: Loads are secured via embedded track grid that uses electromagnetic clamping.

---

Use Cases

* Long-haul freight between industrial hubs

* Emergency logistics in disaster zones (roads optional)

* Military and spaceport ground transport

* Futuristic cities where noise, emissions, and traffic footprint must be minimal

---

The Aeon Atlas hovercraft cargo hauler provides several substantial environmental benefits compared to traditional diesel-powered trucks:

---

1. Zero Tailpipe Emissions

* Fully electric propulsion means no CO₂, NOₓ, or particulate emissions.

* Reduces urban air pollution, improving health in populated areas and logistics corridors.

---

2. Ultra-Quiet Operation

* Electric lift fans and thrusters are significantly quieter than combustion engines.

* Minimizes noise pollution, especially near residential zones and at night.

---

3. Renewable Energy Compatibility

* Can be powered by solar, wind, or grid-based renewable sources.

* Optional solar skin contributes auxiliary power for internal systems and passive charging.

---

4. Reduced Road Wear

* By hovering instead of rolling on wheels, it doesn't degrade asphalt or produce microplastic tire debris.

* Reduces need for frequent road repairs, lowering associated material and energy costs.

---

5. Modular, Sustainable Construction

* Chassis made of recyclable carbon composites and modular battery packs.

* Reduces waste and allows for efficient upgrades and end-of-life recycling.

---

6. Terrain Independence

* Can operate on unpaved ground, reducing the need to build or maintain additional roads in rural or sensitive environments (e.g., wetlands, forests).

---

7. Smart Routing for Energy Efficiency

* AI-assisted route planning avoids congestion and terrain inefficiencies.

* Minimizes energy use per trip compared to legacy truck convoys.

---

8. Fewer Vehicles, Higher Efficiency

* High cargo capacity and precise maneuvering reduce the need for multiple smaller delivery vehicles.

---

Project Name: Aeon Atlas

Core Capabilities

* Electric hovercraft propulsion: Utilizes directed air cushion technology for lift, with vectored thrusters for propulsion and maneuvering.

* On-road + off-road: Optimized for paved surfaces but capable of operating on gravel, sand, or shallow water.

* Cargo capacity: Up to 40 tons, equivalent to a Class 8 truck (semi).

* Modular payload: Flatbed-style cargo platform allows containerized shipping, modular compartments, or open storage.

---

Design Aesthetic: “Alien Utility”

Rather than wheels and chassis, it looks like a fusion of an airship, lunar lander, and monolithic utility craft. Think Star Wars meets Tesla Semi with the elegance of industrial minimalism.

Key Design Features

Hover Base

* Maglev-Assisted Skirt: Low-friction hybrid skirt with segmented directional nozzles. Reinforced side skirts pulse dynamically to maintain cushion shape.

* Shape: Rounded hexagon or teardrop base (30–40 ft long) with a wide rear and tapered front for aerodynamic lift and controlled lateral movement.

* Ground clearance: Adjustable 0.5–3 feet hover height using AI-stabilized lift fans and magnetic assist pads.

Main Body

* Cockpit: Central, elevated command pod with 360° panoramic OLED canopy. The pilot sits like in a drone control station, slightly elevated, not traditional driving.

* Structure: Monocoque carbon-composite shell. Matte or pearlescent finish with embedded LED trim lines for visibility and ambient signaling.

* No windows or grille—all sensors and cameras.

Propulsion and Power

* Lift System: 12 axial lift fans embedded in the base platform powered by dual solid-state battery banks.

* Thrust System: Rear-mounted vectored plasma duct fans for directional speed. Front lateral fans for drift and stability.

* Range: 500–700 miles per charge with regenerative hover braking.

* Solar-Skin Option: Semi-transparent graphene solar layer across flat upper panels.

---

Tech and Autonomy

* Drive-by-wire + AI Co-pilot: Fully autonomous with human override for navigation in mixed traffic.

* Road-ready: Visual light and lidar systems project “virtual wheels” for surrounding vehicle compliance and law enforcement detection.

* No windshield, mirrors, or visible headlights – all visibility via AR and external projection systems.

* Traffic Integration: Holographic license/ID projection, soundless horn pulses, and standard brake/turn lighting translated from AI behavior.

---

Power System

* Battery Packs: Swappable modules integrated into the underbody.

* Cooling System: Liquid-cooled superconducting circuits with radiant cooling fins visible at the rear like a spaceship engine block.

* Charging: Fast-charging via inductive ground stations or tethered plug-ins at hover depots.

---

Cargo Handling

* Automated Docking Bay: Rear or side entry ports that align with logistics centers.

* Magnetic Locking Pallet System: Loads are secured via embedded track grid that uses electromagnetic clamping.

---

Use Cases

* Long-haul freight between industrial hubs

* Emergency logistics in disaster zones (roads optional)

* Military and spaceport ground transport

* Futuristic cities where noise, emissions, and traffic footprint must be minimal

---

The Aeon Atlas hovercraft cargo hauler provides several substantial environmental benefits compared to traditional diesel-powered trucks:

---

1. Zero Tailpipe Emissions

* Fully electric propulsion means no CO₂, NOₓ, or particulate emissions.

* Reduces urban air pollution, improving health in populated areas and logistics corridors.

---

2. Ultra-Quiet Operation

* Electric lift fans and thrusters are significantly quieter than combustion engines.

* Minimizes noise pollution, especially near residential zones and at night.

---

3. Renewable Energy Compatibility

* Can be powered by solar, wind, or grid-based renewable sources.

* Optional solar skin contributes auxiliary power for internal systems and passive charging.

---

4. Reduced Road Wear

* By hovering instead of rolling on wheels, it doesn't degrade asphalt or produce microplastic tire debris.

* Reduces need for frequent road repairs, lowering associated material and energy costs.

---

5. Modular, Sustainable Construction

* Chassis made of recyclable carbon composites and modular battery packs.

* Reduces waste and allows for efficient upgrades and end-of-life recycling.

---

6. Terrain Independence

* Can operate on unpaved ground, reducing the need to build or maintain additional roads in rural or sensitive environments (e.g., wetlands, forests).

---

7. Smart Routing for Energy Efficiency

* AI-assisted route planning avoids congestion and terrain inefficiencies.

* Minimizes energy use per trip compared to legacy truck convoys.

---

8. Fewer Vehicles, Higher Efficiency

* High cargo capacity and precise maneuvering reduce the need for multiple smaller delivery vehicles.

Figure 1.

Figure 2.

commentComments

Click here for more information.

No Comments.

Cookies Notice

We use cookies to ensure that we give you the best experience on our website. By continuing to visit this site you agree to our use of cookies.

Click here for more information about the use of cookies on our website.

Click here for more information about the use of cookies on our website.