Optimized road surface designed to achieve minimal friction noise | post-ideas.com

Optimized road surface designed to achieve minimal friction noise

Here is s a practical, build-ready road surface concept tuned specifically to suppress tire–pavement (friction) noise, plus variants for different climates and traffic mixes. This road is intended to pass through regions with a temperate climate.

Target: what we’re minimizing

Main noise mechanisms at road speeds (>30–40 km/h) are:

* Air pumping in/out of tread grooves and surface voids

* Stick–slip at micro-contact points

* Tread block impact on coarse texture/edges

* Resonances in tread cavities and voids

The recipe is to: (1) absorb and vent air pulses, (2) smooth high, sharp texture without making it slick, and (3) break up tonal peaks.

---

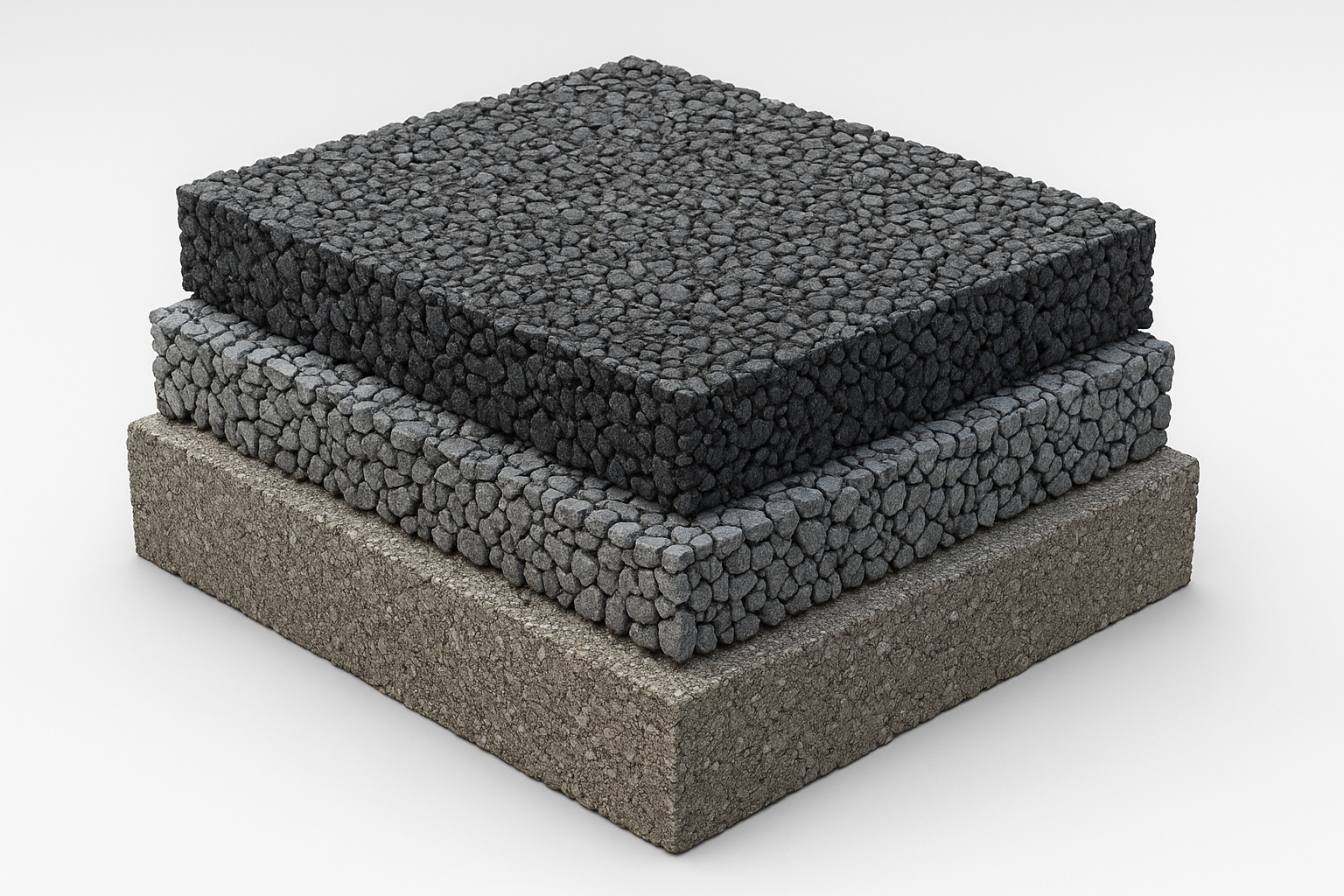

Baseline low-noise design (asphalt): Double-Layer Porous Asphalt (DLPA)

Use when: temperate/warm climates, high ADT, speed ≥50 km/h, noise priority is high.

Cross-section

* Top layer (wearing/“acoustic” layer)

* Thickness: 20–25 mm

* Nominal max aggregate size (NMAS): 4 mm (0/4)

* Voids in mix (VIM): 20–22% (in-place 18–20%)

* Binder: polymer-modified (PMB) or crumb-rubber modified; target 4.8–5.2% by mass of mix (optimize by gyratory).

* Additives: cellulose fibers 0.3–0.5% to stabilize binder; hydrated lime 1–1.5% for adhesion & durability.

* Texture: negative macrotexture, mean profile depth (MPD) 0.6–0.9 mm; microtexture maintained via high-PSV aggregates.

* Bottom layer (drainage/acoustic sublayer)

* Thickness: 30–40 mm

* NMAS: 8 mm (0/8) open-graded

* VIM: 18–20% (in-place 16–18%)

* Binder: PMB, \~4.6–5.0%

* Function: provides vertical porosity and acoustic “backing” to the top layer and drains laterally.

* Drainage & support

* Edge/longitudinal underdrains every 30–50 m, outlet falls ≥1%.

* Impermeable bond breaker/tack to prevent water into base if needed.

* Base: stiff, even (IRI ≤ 1.2 m/km) to avoid dynamic tire loading.

Materials

* Aggregates: durable, high PSV (≥55), low LA abrasion (≤25), cubical; minimize flaky particles.

* Binder: SBS-modified or crumb-rubber modified for elasticity and rut resistance.

* Fines: minimal; keep mastic supple (voids must stay open).

Acoustic performance you can expect

* A-weighted pass-by reduction: typically 4–6 dB vs dense asphalt; 6–8 dB vs transversely-tined concrete, depending on speed and tire set.

* Tonal peak control: small NMAS top layer + porous backing damps tread-cavity resonances (1–1.5 kHz band).

Safety (wet & winter)

* Skid: BPN/SRT in design ≥60; maintain macro MPD ≥0.5 mm.

* Hydroplaning: OG structure lowers risk; ensure lateral drainage path length <6 m to outlets.

* Freeze–thaw: require anti-stripping agent/lime; winter maintenance plan to avoid fines clogging.

Construction notes (critical for noise)

* Lay at low compaction energy just enough to lock aggregate; preserve voids.

* Pave warm & dry (pavement >15 °C, no rain; wind <20 km/h).

* Joint matching tolerance ≤3 mm; any lift offset will reintroduce impact noise.

* Use light-textured steel rollers; avoid pneumatic tires that smear/close pores.

QA/QC & acceptance

* Void content (cores): top 18–20%, bottom 16–18%.

* Permeability: in situ ≥200 ml/15 s (Falling Head) or k ≥ 0.8×10⁻³ m/s.

* Texture: MPD by laser, 0.6–0.9 mm.

* Acoustics: CPX or OBSI after 7–14 days; set acceptance ≤ 96–98 dB(A) CPX at 80 km/h (specify method & tires).

* Smoothness: IRI ≤1.2 m/km.

Maintenance to preserve low noise

* Vacuum sweeping: regenerative air/vacuum trucks, monthly in leaf seasons; quarterly otherwise.

* Pore rejuvenation: high-pressure water + vacuum if permeability < threshold.

* Thin micro-overlay (ultra-thin PA 0/3, 10–12 mm) at year 6–8 if noise rises >2 dB.

* Crack sealing: use flexible low-modulus sealants; avoid overbanding ridges.

---

Concrete corridor alternative: NGCS (Next-Generation Concrete Surface)

Use when: rigid pavement is required or porosity is undesirable (heavy freeze–thaw, high debris load).

* Process: diamond grinding (flush-cut) + longitudinal grooves (uniform, low land-area) → negative texture without sharp asperities.

* Texture targets: mean texture depth 0.4–0.6 mm; groove width 2.5–3.2 mm, spacing 5–8 mm, land width 2–3 mm.

* Expected reduction: 3–5 dB vs conventional tining; good durability (10+ years).

* Hydroplaning: longitudinal orientation preserves drainage; ensure cross-slope ≥2%.

---

Ultra-low option (pilot): Poroelastic Road Surface (PERS)

Use when: maximum noise reduction needed near sensitive receptors and you accept shorter life/pilot risk.

* Make-up: \~80–85% rubber granulate (recycled tire) + 15–20% polyurethane binder over a stiff base; thickness 30–40 mm.

* Noise: additional 3–6 dB lower than DLPA (often the quietest pavement).

* Caveats: temperature sensitivity, raveling risk, snowplow wear; use in low-speed urban segments or as test sections with rapid-repair plan.

---

Tire–pavement system tuning

* Break up tonal peaks: small NMAS (4 mm) + randomized microtexture via multi-source aggregates.

* Avoid sharp edges: no exposed large chippings; if using SMA, choose 0/8 with light surface grind to knock down asperities.

* Seal cavity resonances: DLPA’s double layer acts as acoustic backing; ensure contrast in top/bottom gradations.

---

Climate & operations playbook

* Wet/cold (freeze–thaw): prefer NGCS or PA with lower VIM (16–18%), stronger PMB, and aggressive anti-stripping + winter sweeping policy.

* Hot rutting risk: increase binder PM level and select stiffer aggregate skeleton (draindown control via fibers).

* Dusty/leafy corridors: design for easy sweeping access; add more outlets; consider self-cleaning slope toward shoulders.

---

Measurement plan (to prove it worked)

* Before/after acoustics: CPX (reference SRTT + AAV tires) at 50/80 km/h; or OBSI with reference tires.

* Texture: laser MPD grid every 50 m for the first 1 km; correlate with noise.

* Permeability & clogging: quarterly permeability checks for first 2 years.

* Trigger points: if noise +2 dB or k < 0.5×10⁻³ m/s, schedule cleaning/rejuvenation.

---

* Surface: Double-Layer Porous Asphalt

* Top: 20–25 mm, 0/4 OG, VIM 18–20% in place, PMB 4.8–5.2%, fibers 0.4%, lime 1.2%, MPD 0.6–0.9 mm

* Bottom: 30–40 mm, 0/8 OG, VIM 16–18%, PMB 4.6–5.0%

* Smoothness: IRI ≤1.2 m/km; Joints ≤3 mm offset

* Permeability: k ≥0.8×10⁻³ m/s (top)

* Acoustics (acceptance): CPX ≤98 dB(A) at 80 km/h (method & tires specified)

* Drainage: underdrains @ 30–50 m, cross-slope ≥2%

* Maintenance: vacuum sweep monthly in leaf season; quarterly otherwise

---

B E N E F I T S

Here is a breakdown of the benefits of the innovative low-noise double-layer porous asphalt road for people, animals, and the environment:

---

For People

* Lower traffic noise: Reduces tire–road noise by 4–6 dB (subjectively \~halving perceived loudness), improving living conditions for nearby communities.

* Improved health: Less chronic noise exposure means lower risks of stress, sleep disturbance, and cardiovascular problems.

* Enhanced comfort: Quieter driving experience inside vehicles.

* Better safety: High skid resistance and rapid surface water drainage reduce hydroplaning and braking distances.

* Smoother ride: Even texture and reduced vibration benefit drivers and passengers.

---

For Animals

* Reduced disturbance: Lower traffic noise minimizes stress and behavioral disruption for wildlife living near roads.

* Improved communication: Many animals (birds, amphibians, insects) rely on sound; quieter roads reduce masking of their calls.

* Safer crossings: Porous asphalt reduces glare and standing water, potentially lowering the risk of animals slipping or being drawn to puddles near the road.

---

For the Environment

* Noise pollution control: A direct passive measure that doesn’t require barriers or walls, preserving landscape aesthetics.

* Water management: Porous layers allow rainfall to drain faster, filtering particulates and reducing polluted runoff into waterways.

* Urban heat mitigation: Open-graded surfaces often retain less heat than dense concrete, lowering localized “heat island” effects.

* Recycling potential: Can incorporate reclaimed asphalt, crumb rubber, or other recycled materials (e.g., tire rubber in binder).

* Biodiversity protection: Lower acoustic footprint preserves habitats near transportation corridors.

---

In summary, the design goes beyond just reducing noise for drivers: it creates a quieter, safer, and more ecologically sensitive roadway that benefits both human communities and surrounding ecosystems.

Target: what we’re minimizing

Main noise mechanisms at road speeds (>30–40 km/h) are:

* Air pumping in/out of tread grooves and surface voids

* Stick–slip at micro-contact points

* Tread block impact on coarse texture/edges

* Resonances in tread cavities and voids

The recipe is to: (1) absorb and vent air pulses, (2) smooth high, sharp texture without making it slick, and (3) break up tonal peaks.

---

Baseline low-noise design (asphalt): Double-Layer Porous Asphalt (DLPA)

Use when: temperate/warm climates, high ADT, speed ≥50 km/h, noise priority is high.

Cross-section

* Top layer (wearing/“acoustic” layer)

* Thickness: 20–25 mm

* Nominal max aggregate size (NMAS): 4 mm (0/4)

* Voids in mix (VIM): 20–22% (in-place 18–20%)

* Binder: polymer-modified (PMB) or crumb-rubber modified; target 4.8–5.2% by mass of mix (optimize by gyratory).

* Additives: cellulose fibers 0.3–0.5% to stabilize binder; hydrated lime 1–1.5% for adhesion & durability.

* Texture: negative macrotexture, mean profile depth (MPD) 0.6–0.9 mm; microtexture maintained via high-PSV aggregates.

* Bottom layer (drainage/acoustic sublayer)

* Thickness: 30–40 mm

* NMAS: 8 mm (0/8) open-graded

* VIM: 18–20% (in-place 16–18%)

* Binder: PMB, \~4.6–5.0%

* Function: provides vertical porosity and acoustic “backing” to the top layer and drains laterally.

* Drainage & support

* Edge/longitudinal underdrains every 30–50 m, outlet falls ≥1%.

* Impermeable bond breaker/tack to prevent water into base if needed.

* Base: stiff, even (IRI ≤ 1.2 m/km) to avoid dynamic tire loading.

Materials

* Aggregates: durable, high PSV (≥55), low LA abrasion (≤25), cubical; minimize flaky particles.

* Binder: SBS-modified or crumb-rubber modified for elasticity and rut resistance.

* Fines: minimal; keep mastic supple (voids must stay open).

Acoustic performance you can expect

* A-weighted pass-by reduction: typically 4–6 dB vs dense asphalt; 6–8 dB vs transversely-tined concrete, depending on speed and tire set.

* Tonal peak control: small NMAS top layer + porous backing damps tread-cavity resonances (1–1.5 kHz band).

Safety (wet & winter)

* Skid: BPN/SRT in design ≥60; maintain macro MPD ≥0.5 mm.

* Hydroplaning: OG structure lowers risk; ensure lateral drainage path length <6 m to outlets.

* Freeze–thaw: require anti-stripping agent/lime; winter maintenance plan to avoid fines clogging.

Construction notes (critical for noise)

* Lay at low compaction energy just enough to lock aggregate; preserve voids.

* Pave warm & dry (pavement >15 °C, no rain; wind <20 km/h).

* Joint matching tolerance ≤3 mm; any lift offset will reintroduce impact noise.

* Use light-textured steel rollers; avoid pneumatic tires that smear/close pores.

QA/QC & acceptance

* Void content (cores): top 18–20%, bottom 16–18%.

* Permeability: in situ ≥200 ml/15 s (Falling Head) or k ≥ 0.8×10⁻³ m/s.

* Texture: MPD by laser, 0.6–0.9 mm.

* Acoustics: CPX or OBSI after 7–14 days; set acceptance ≤ 96–98 dB(A) CPX at 80 km/h (specify method & tires).

* Smoothness: IRI ≤1.2 m/km.

Maintenance to preserve low noise

* Vacuum sweeping: regenerative air/vacuum trucks, monthly in leaf seasons; quarterly otherwise.

* Pore rejuvenation: high-pressure water + vacuum if permeability < threshold.

* Thin micro-overlay (ultra-thin PA 0/3, 10–12 mm) at year 6–8 if noise rises >2 dB.

* Crack sealing: use flexible low-modulus sealants; avoid overbanding ridges.

---

Concrete corridor alternative: NGCS (Next-Generation Concrete Surface)

Use when: rigid pavement is required or porosity is undesirable (heavy freeze–thaw, high debris load).

* Process: diamond grinding (flush-cut) + longitudinal grooves (uniform, low land-area) → negative texture without sharp asperities.

* Texture targets: mean texture depth 0.4–0.6 mm; groove width 2.5–3.2 mm, spacing 5–8 mm, land width 2–3 mm.

* Expected reduction: 3–5 dB vs conventional tining; good durability (10+ years).

* Hydroplaning: longitudinal orientation preserves drainage; ensure cross-slope ≥2%.

---

Ultra-low option (pilot): Poroelastic Road Surface (PERS)

Use when: maximum noise reduction needed near sensitive receptors and you accept shorter life/pilot risk.

* Make-up: \~80–85% rubber granulate (recycled tire) + 15–20% polyurethane binder over a stiff base; thickness 30–40 mm.

* Noise: additional 3–6 dB lower than DLPA (often the quietest pavement).

* Caveats: temperature sensitivity, raveling risk, snowplow wear; use in low-speed urban segments or as test sections with rapid-repair plan.

---

Tire–pavement system tuning

* Break up tonal peaks: small NMAS (4 mm) + randomized microtexture via multi-source aggregates.

* Avoid sharp edges: no exposed large chippings; if using SMA, choose 0/8 with light surface grind to knock down asperities.

* Seal cavity resonances: DLPA’s double layer acts as acoustic backing; ensure contrast in top/bottom gradations.

---

Climate & operations playbook

* Wet/cold (freeze–thaw): prefer NGCS or PA with lower VIM (16–18%), stronger PMB, and aggressive anti-stripping + winter sweeping policy.

* Hot rutting risk: increase binder PM level and select stiffer aggregate skeleton (draindown control via fibers).

* Dusty/leafy corridors: design for easy sweeping access; add more outlets; consider self-cleaning slope toward shoulders.

---

Measurement plan (to prove it worked)

* Before/after acoustics: CPX (reference SRTT + AAV tires) at 50/80 km/h; or OBSI with reference tires.

* Texture: laser MPD grid every 50 m for the first 1 km; correlate with noise.

* Permeability & clogging: quarterly permeability checks for first 2 years.

* Trigger points: if noise +2 dB or k < 0.5×10⁻³ m/s, schedule cleaning/rejuvenation.

---

* Surface: Double-Layer Porous Asphalt

* Top: 20–25 mm, 0/4 OG, VIM 18–20% in place, PMB 4.8–5.2%, fibers 0.4%, lime 1.2%, MPD 0.6–0.9 mm

* Bottom: 30–40 mm, 0/8 OG, VIM 16–18%, PMB 4.6–5.0%

* Smoothness: IRI ≤1.2 m/km; Joints ≤3 mm offset

* Permeability: k ≥0.8×10⁻³ m/s (top)

* Acoustics (acceptance): CPX ≤98 dB(A) at 80 km/h (method & tires specified)

* Drainage: underdrains @ 30–50 m, cross-slope ≥2%

* Maintenance: vacuum sweep monthly in leaf season; quarterly otherwise

---

B E N E F I T S

Here is a breakdown of the benefits of the innovative low-noise double-layer porous asphalt road for people, animals, and the environment:

---

For People

* Lower traffic noise: Reduces tire–road noise by 4–6 dB (subjectively \~halving perceived loudness), improving living conditions for nearby communities.

* Improved health: Less chronic noise exposure means lower risks of stress, sleep disturbance, and cardiovascular problems.

* Enhanced comfort: Quieter driving experience inside vehicles.

* Better safety: High skid resistance and rapid surface water drainage reduce hydroplaning and braking distances.

* Smoother ride: Even texture and reduced vibration benefit drivers and passengers.

---

For Animals

* Reduced disturbance: Lower traffic noise minimizes stress and behavioral disruption for wildlife living near roads.

* Improved communication: Many animals (birds, amphibians, insects) rely on sound; quieter roads reduce masking of their calls.

* Safer crossings: Porous asphalt reduces glare and standing water, potentially lowering the risk of animals slipping or being drawn to puddles near the road.

---

For the Environment

* Noise pollution control: A direct passive measure that doesn’t require barriers or walls, preserving landscape aesthetics.

* Water management: Porous layers allow rainfall to drain faster, filtering particulates and reducing polluted runoff into waterways.

* Urban heat mitigation: Open-graded surfaces often retain less heat than dense concrete, lowering localized “heat island” effects.

* Recycling potential: Can incorporate reclaimed asphalt, crumb rubber, or other recycled materials (e.g., tire rubber in binder).

* Biodiversity protection: Lower acoustic footprint preserves habitats near transportation corridors.

---

In summary, the design goes beyond just reducing noise for drivers: it creates a quieter, safer, and more ecologically sensitive roadway that benefits both human communities and surrounding ecosystems.

commentComments

Click here for more information.

No Comments.

Cookies Notice

We use cookies to ensure that we give you the best experience on our website. By continuing to visit this site you agree to our use of cookies.

Click here for more information about the use of cookies on our website.

Click here for more information about the use of cookies on our website.