Innovative, mass-producible sound insulation system for residential spaces | post-ideas.com

Innovative, mass-producible sound insulation system for residential spaces

Below is a concept-to-production design for an innovative, mass-producible residential sound insulation system. It balances high acoustic performance, low cost, easy installation, sustainability, and scalability, making it suitable for apartments, condos, and single-family homes.

---

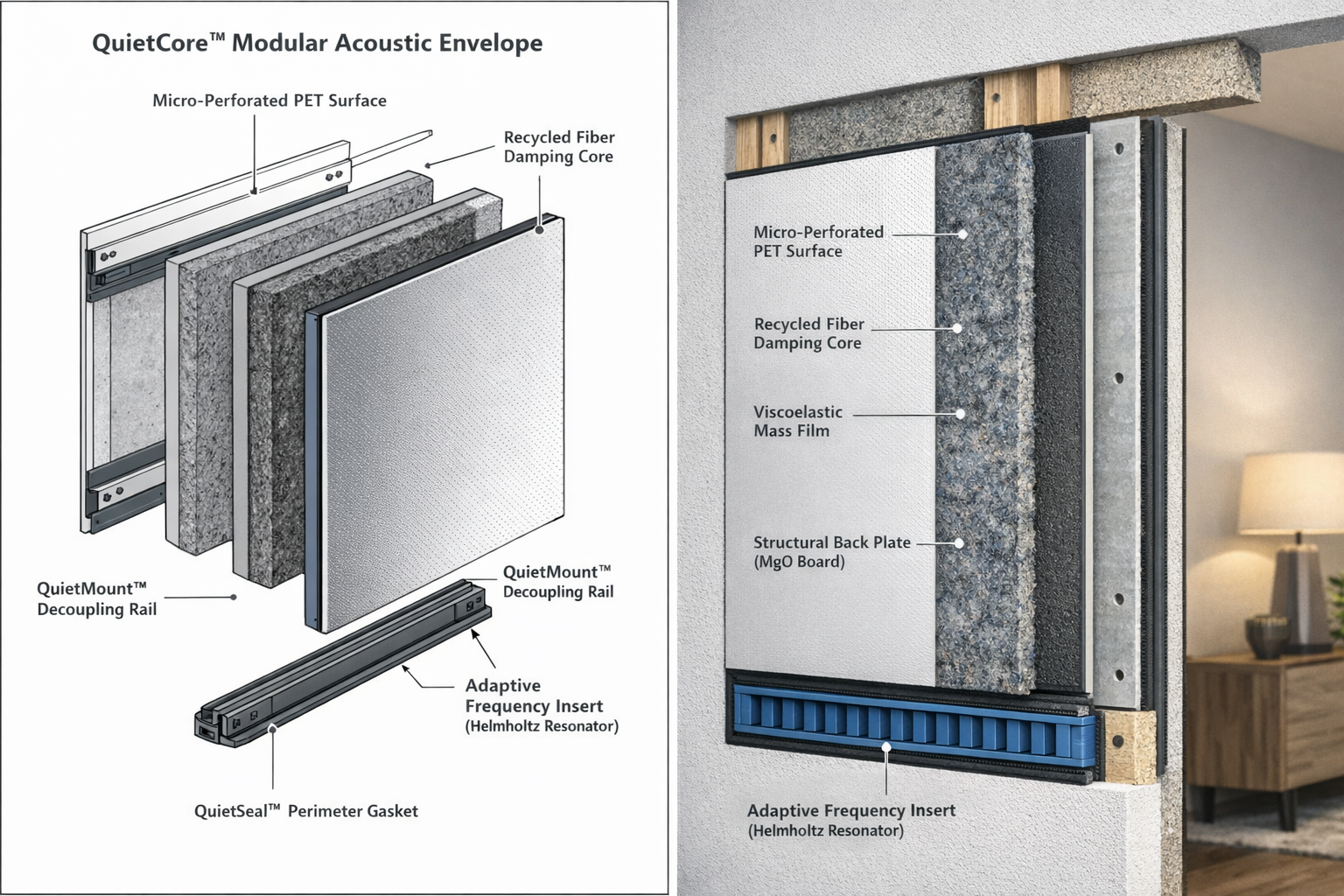

System Name: QuietCore™ Modular Acoustic Envelope

---

Core Design Philosophy

Instead of relying on a single thick barrier (traditional drywall + insulation), QuietCore™ uses a hybrid multilayer approach that targets all three sound paths:

1. Airborne sound (voices, TV, traffic)

2. Structure-borne vibration (footsteps, bass)

3. Sound leakage (gaps, outlets, seams)

This is achieved using mass–spring–damping principles, optimized for residential constraints.

---

System Overview

1. Modular Acoustic Panels (Primary Barrier)

Size: 600 × 1200 mm (standard drywall-compatible)

Thickness: 32 mm

Weight: ~12 kg per panel

Layer Stack (front → back)

1. Micro-perforated PET skin

* Controls mid/high frequencies

* Durable and paintable

2. Recycled Fiber Damping Core

* Mix of recycled denim + PET fibers

* Tuned density gradient (softer center, denser edges)

3. Viscoelastic Mass Film

* Thin polymer layer (MLV alternative)

* Converts vibration into heat

4. Structural Back Plate

* Magnesium oxide or fiber cement

* Fire-resistant, mold-proof

Performance:

* NRC: 0.85

* STC (wall system): 58–62 (with studs)

---

2. Decoupling Mount System (Vibration Control)

QuietMount™ Rail System

* Recycled rubber + glass fiber composite rails

* Snaps into wall studs or concrete anchors

* Panel floats 6–10 mm off structure

Benefits

* Reduces structure-borne sound by up to 70%

* No resilient channel bending issues

* Tool-less snap fit for installers

---

3. Smart Edge Sealing System (Leak Prevention)

QuietSeal™ Perimeter Gasket

* Pre-attached thermoplastic elastomer gasket

* Compresses when panels interlock

* Self-healing around screws and outlets

Critical Innovation

> Most real-world sound failure occurs at seams—not materials.

---

4. Adaptive Frequency Inserts (Optional Upgrade)

For bedrooms, home theaters, or music rooms:

* Slot-in Helmholtz micro-resonator strips

* Tuned for:

* 80–125 Hz (bass/footsteps)

* 250–500 Hz (speech)

These inserts snap into rear cavities without altering wall depth.

---

Manufacturing & Scalability

Materials (Mass-Production Friendly)

| Component | Material | Reason |

| ---------- | ------------------ | --------------------- |

| Core | Recycled PET/denim | Cheap, sustainable |

| Mass film | Polymer composite | Roll-to-roll scalable |

| Back plate | MgO board | Fire rated, stable |

| Rails | Rubber composite | Extrusion-friendly |

Manufacturing Process

1. Fiber core compression molding

2. Lamination with viscoelastic film

3. Automated panel cutting

4. Gasket overmolding

5. Rail extrusion (separate line)

Factories can repurpose existing drywall & insulation lines

---

Installation (DIY or Pro)

Install Time: ~30–40% faster than drywall

Skill Level: Medium (DIY possible)

Steps:

1. Mount QuietMount™ rails

2. Snap panels into place

3. Seal perimeter (pre-attached)

4. Paint or finish surface

No mudding, sanding, or curing time.

---

Performance vs Traditional Walls

| System | STC | Thickness | Install Time |

| ------------------- | --------- | ---------- | ------------ |

| Standard drywall | 33–36 | 125 mm | Long |

| Double drywall + RC | 50–55 | 150 mm | Complex |

| QuietCore™ | 58–62 | 132 mm | Fast |

---

Sustainability & Compliance

* ≥60% recycled content

* Low-VOC, formaldehyde-free

* Fire rating: ASTM E84 Class A

* Designed for disassembly & recycling

---

Market Applications

* Apartment retrofits

* New residential developments

* Home offices & bedrooms

* Short-term rental noise control

* Urban housing near transit

---

Optional Future Add-Ons

* Active noise cancellation module (low-frequency only)

* Integrated thermal insulation variant

* Smart vibration sensors for noise diagnostics

---

System Name: QuietCore™ Modular Acoustic Envelope

---

Core Design Philosophy

Instead of relying on a single thick barrier (traditional drywall + insulation), QuietCore™ uses a hybrid multilayer approach that targets all three sound paths:

1. Airborne sound (voices, TV, traffic)

2. Structure-borne vibration (footsteps, bass)

3. Sound leakage (gaps, outlets, seams)

This is achieved using mass–spring–damping principles, optimized for residential constraints.

---

System Overview

1. Modular Acoustic Panels (Primary Barrier)

Size: 600 × 1200 mm (standard drywall-compatible)

Thickness: 32 mm

Weight: ~12 kg per panel

Layer Stack (front → back)

1. Micro-perforated PET skin

* Controls mid/high frequencies

* Durable and paintable

2. Recycled Fiber Damping Core

* Mix of recycled denim + PET fibers

* Tuned density gradient (softer center, denser edges)

3. Viscoelastic Mass Film

* Thin polymer layer (MLV alternative)

* Converts vibration into heat

4. Structural Back Plate

* Magnesium oxide or fiber cement

* Fire-resistant, mold-proof

Performance:

* NRC: 0.85

* STC (wall system): 58–62 (with studs)

---

2. Decoupling Mount System (Vibration Control)

QuietMount™ Rail System

* Recycled rubber + glass fiber composite rails

* Snaps into wall studs or concrete anchors

* Panel floats 6–10 mm off structure

Benefits

* Reduces structure-borne sound by up to 70%

* No resilient channel bending issues

* Tool-less snap fit for installers

---

3. Smart Edge Sealing System (Leak Prevention)

QuietSeal™ Perimeter Gasket

* Pre-attached thermoplastic elastomer gasket

* Compresses when panels interlock

* Self-healing around screws and outlets

Critical Innovation

> Most real-world sound failure occurs at seams—not materials.

---

4. Adaptive Frequency Inserts (Optional Upgrade)

For bedrooms, home theaters, or music rooms:

* Slot-in Helmholtz micro-resonator strips

* Tuned for:

* 80–125 Hz (bass/footsteps)

* 250–500 Hz (speech)

These inserts snap into rear cavities without altering wall depth.

---

Manufacturing & Scalability

Materials (Mass-Production Friendly)

| Component | Material | Reason |

| ---------- | ------------------ | --------------------- |

| Core | Recycled PET/denim | Cheap, sustainable |

| Mass film | Polymer composite | Roll-to-roll scalable |

| Back plate | MgO board | Fire rated, stable |

| Rails | Rubber composite | Extrusion-friendly |

Manufacturing Process

1. Fiber core compression molding

2. Lamination with viscoelastic film

3. Automated panel cutting

4. Gasket overmolding

5. Rail extrusion (separate line)

Factories can repurpose existing drywall & insulation lines

---

Installation (DIY or Pro)

Install Time: ~30–40% faster than drywall

Skill Level: Medium (DIY possible)

Steps:

1. Mount QuietMount™ rails

2. Snap panels into place

3. Seal perimeter (pre-attached)

4. Paint or finish surface

No mudding, sanding, or curing time.

---

Performance vs Traditional Walls

| System | STC | Thickness | Install Time |

| ------------------- | --------- | ---------- | ------------ |

| Standard drywall | 33–36 | 125 mm | Long |

| Double drywall + RC | 50–55 | 150 mm | Complex |

| QuietCore™ | 58–62 | 132 mm | Fast |

---

Sustainability & Compliance

* ≥60% recycled content

* Low-VOC, formaldehyde-free

* Fire rating: ASTM E84 Class A

* Designed for disassembly & recycling

---

Market Applications

* Apartment retrofits

* New residential developments

* Home offices & bedrooms

* Short-term rental noise control

* Urban housing near transit

---

Optional Future Add-Ons

* Active noise cancellation module (low-frequency only)

* Integrated thermal insulation variant

* Smart vibration sensors for noise diagnostics

Figure 1.

commentComments

Click here for more information.

No Comments.

Cookies Notice

We use cookies to ensure that we give you the best experience on our website. By continuing to visit this site you agree to our use of cookies.

Click here for more information about the use of cookies on our website.

Click here for more information about the use of cookies on our website.